DTF (Direct-to-Fabric) Printing Equipment revolutionizes custom apparel manufacturing by directly applying inks to fabrics, minimizing waste and maximizing productivity. With advanced features like automated feeding mechanisms and precise temperature control, these printers streamline production, reduce labor costs, and foster customer satisfaction through faster turnaround times. Regular maintenance, proper material preparation, efficient inventory management, and strategic use of high-quality transfers ensure optimal DTF printing performance, reducing waste and minimizing downtime for clean, eco-friendly operations.

Looking to streamline your printing processes and cut waste? Discover how DTF Printing Equipment offers a revolutionary solution. This article delves into the world of efficient DTF printing, exploring its role in minimizing downtime and reducing waste compared to traditional methods. We’ll uncover key features making DTF systems stand out, followed by actionable strategies to maximize their potential. Optimize your workflow with these insights on DTF Printing Equipment.

- Understanding DTF Printing Equipment: Its Role in Waste Reduction

- Key Features of Efficient DTF Printing Systems

- Strategies for Maximizing Efficiency and Minimizing Downtime with DTF Printers

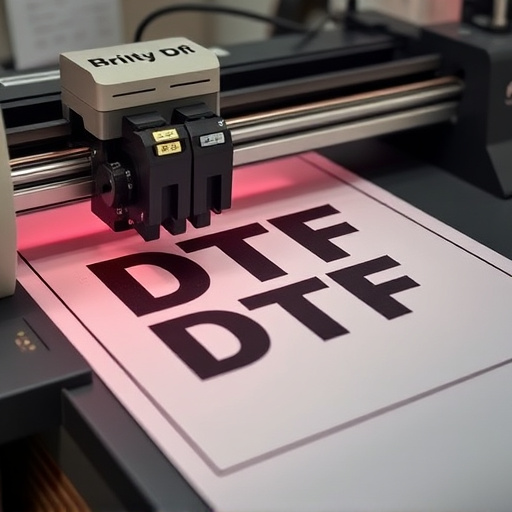

Understanding DTF Printing Equipment: Its Role in Waste Reduction

DTF (Direct-to-Fabric) Printing Equipment plays a pivotal role in minimizing waste and maximizing productivity in the printing industry, especially for custom apparel and textile businesses. This advanced technology allows for precise and efficient transfer of designs onto various fabrics, eliminating the need for wasteful intermediate steps. By directly applying inks to the fabric surface, DTF printing reduces the amount of material wasted during the printing process.

Moreover, DTF Printing Equipment streamlines the production process, cutting down on downtime and labor costs. Its ability to handle bulk orders with speed and precision ensures that businesses can meet high demand while maintaining a clean, eco-friendly operation. This is particularly advantageous for companies offering personalized dtf printing services, as it enables them to offer faster turnaround times without compromising quality, thereby fostering customer satisfaction and loyalty.

Key Features of Efficient DTF Printing Systems

Efficient DTF printing systems stand out with their sophisticated features designed to streamline production and minimize waste. Among the key benefits are automated feeding mechanisms that ensure consistent, error-free loading of designs onto transfer sheets, reducing downtime caused by manual adjustments. These systems also incorporate advanced heating elements that deliver precise temperature control, resulting in high-quality DTF transfers with crisp details and vibrant colors.

Additionally, modern DTF printing equipment offers versatile connectivity options, allowing for seamless integration with dtf online ordering platforms and digital design software. Custom DTF gang sheets are another notable feature, enabling users to produce batches of customized transfers efficiently. This level of customization not only caters to diverse client needs but also contributes to cost-effectiveness by maximizing the use of each print run.

Strategies for Maximizing Efficiency and Minimizing Downtime with DTF Printers

To maximize efficiency and minimize downtime with DTF (Direct to Fabric) printers, several strategic approaches can be implemented. Firstly, regular maintenance checks are essential to ensure optimal performance. This includes cleaning the printer regularly, checking ink levels, and replacing worn-out parts promptly. Secondly, proper material preparation is key; using high-quality DTF transfers designed for your specific fabric types ensures consistent and accurate printing results, reducing waste due to misaligned or failed transfers.

Additionally, efficient inventory management plays a significant role. Keep a well-organized stock of DTF custom apparel in various sizes to cater to diverse customer demands. This minimizes downtime caused by waiting for material preparation, as you can promptly access the required items. Furthermore, staying updated with software and firmware updates ensures your DTF printing equipment remains at peak performance, enabling you to produce high-quality dtf transfers faster and more reliably.

In conclusion, investing in advanced DTF Printing Equipment offers a powerful solution to reduce waste and minimize downtime in printing processes. By understanding the role of this technology, recognizing its key features, and implementing efficient strategies, businesses can achieve higher productivity and sustainability. Efficient DTF printers streamline operations, ensuring every print job is precise and timely, thereby enhancing overall production quality and reducing environmental impact.