DTF (Direct-to-Film) printing equipment has democratized custom print and transfer production with both entry-level and professional options. Entry-level printers offer user-friendly operations, UV light curing for vibrant prints on diverse materials, and precise control for beginners. Pro-level equipment enhances precision, speed, and control with high-resolution printing, automated feeding, and advanced cutting systems, suitable for complex designs and commercial applications like apparel printing and automotive branding. Customizable settings enable the creation of indelible UV DTF transfers for DTF online ordering, catering to businesses prioritizing high-speed production and outstanding durability.

Unleash your creativity with the latest DTF (Direct to Fabric) printing technology! This guide explores the world of DTF printing equipment, offering a comprehensive look at both entry-level and pro-grade machines. For beginners, we break down essential features and advantages, while advanced users will discover high-end specs and real-world applications. From versatile designs to top-tier performance, this article equips you with the knowledge to choose the perfect DTF printer for your needs.

- Understanding DTF Printing Equipment: A Comprehensive Overview

- Entry-Level DTF Printers: Features and Benefits for Beginners

- Pro-Level DTF Printing: Advanced Specifications and Applications

Understanding DTF Printing Equipment: A Comprehensive Overview

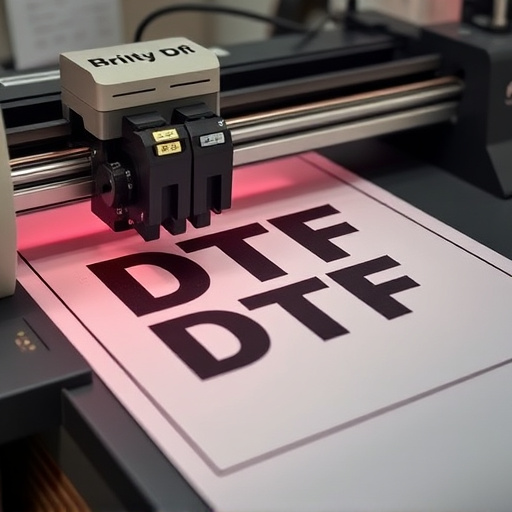

DTF (Direct-to-Film) Printing Equipment is a cutting-edge technology that has revolutionized the way we produce custom prints and transfers. This versatile printing method allows for high-quality, detailed designs to be applied directly onto various materials, from textiles to plastics. Understanding DTF Printing Equipment involves grasping its unique process and the equipment required to achieve exceptional results.

At an entry-level, DTF printers typically offer user-friendly operations with simple controls, making them accessible for beginners. These machines use UV light to cure the ink once applied to the substrate, resulting in vibrant and long-lasting prints. For professionals, advanced pro-level equipment provides enhanced precision, speed, and control over the printing process. Features like high-resolution printing, automated feeding systems, and precise registration ensure consistent output quality. Moreover, the ability to customize settings for different materials and inks enables the production of uv dtf transfers with remarkable clarity and durability, ideal for creating high quality dtf transfers through dtf online ordering.

Entry-Level DTF Printers: Features and Benefits for Beginners

Entry-level DTF printers are an excellent starting point for beginners looking to explore the world of direct-to-film (DTF) printing. These machines often come with user-friendly features designed to simplify the learning curve, making them accessible for those new to this technology. Basic models typically offer automated film loading and unloading, ensuring hassle-free operation. Beginners will appreciate the precision and control provided by these printers, allowing them to produce high-quality DTF transfer printing with consistent results.

Many entry-level DTF printers also include intuitive software that guides users through the application instructions, making it easier to navigate the process. This level of simplicity is ideal for small businesses or hobbyists wanting to experiment with custom designs and personalized products without a steep learning curve. With these printers, beginners can explore their creativity while gaining valuable experience in the direct to film transfers technique.

Pro-Level DTF Printing: Advanced Specifications and Applications

Pro-Level DTF Printing offers advanced features and capabilities tailored for professionals seeking exceptional quality and versatility. This level of equipment is designed to handle complex designs, large formats, and a wide range of materials, making it ideal for commercial applications like custom apparel printing, signage, and even automotive branding. Pro-level machines often incorporate high-resolution printers, precise laminators, and advanced cutting systems, enabling the creation of intricate, indelible direct to film transfers (DTF).

These advanced systems support not only standard DTF transfers but also allow for the production of custom gang sheets, where multiple designs are printed and cut together on a single sheet, streamlining workflow and reducing waste. With their superior specifications, these printers cater to businesses requiring high-speed production, consistent accuracy, and outstanding durability in their final prints.

DTF printing equipment has evolved to cater to both novices and professionals, offering a range of options from entry-level machines to advanced pro-grade models. Whether you’re a beginner looking to dip your toes into the world of direct to fabric (DTF) printing or an experienced practitioner seeking enhanced capabilities, understanding these different levels of technology is key to making an informed decision. By considering the features and benefits outlined in this article, you can choose the ideal DTF printer that aligns with your skills, budget, and desired outcomes, unlocking endless creative possibilities.