DTF Printing Equipment revolutionizes print creation with its direct-to-object (DTO) technology, offering both entry-level and professional machines for diverse users. Entry-level printers provide affordable, durable prints suitable for beginners and small businesses, while professional models boast advanced features like higher resolutions, larger work areas, and enhanced ink options for commercial applications, ensuring superior quality and efficiency in bulk production or specialized services. Direct to Fabric (DTF) printing, utilizing UV light to instantly cure ink on fabrics like cotton, polyester, and nylon, produces vibrant, durable designs perfect for custom apparel and home décor. The market offers a range of DTF equipment catering to varying needs, from affordable entry-level printers to advanced professional models.

“Discover the world of DTF (Direct to Fabric) printing with our comprehensive guide to entry-level and pro-level equipment. From the basics of DTF printing technology to a deep dive into different printer models, we explore what makes each category unique.

Learn about budget-friendly options perfect for beginners, highlighting key features and real-world applications. Then, uncover advanced features of professional-level machines, including enhanced speed, precision, and cutting systems, ideal for commercial use in apparel, home decor, and custom product manufacturing.”

- Understanding DTF Printing Equipment

- – Definition and basic working principle of DTF (Direct to Fabric) printing

- – Types of DTF printers: Entry-level vs Professional models

Understanding DTF Printing Equipment

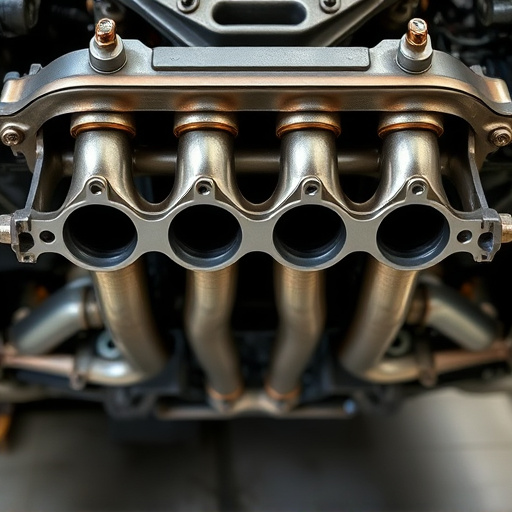

DTF Printing Equipment is a cutting-edge technology that has revolutionized the way we create and reproduce high-quality prints. It involves a process where designs are transferred to various materials, such as textiles or plastics, through a direct-to-object (DTO) method. This equipment offers both entry-level and professional options, catering to diverse user needs.

Entry-level DTF printers are ideal for beginners and small businesses, providing an affordable way to explore this technology. These machines typically use heat to bond ink directly onto the surface of the material, resulting in durable prints. While they may have limited capabilities in terms of size and complexity, they offer excellent value for money and are easy to operate. On the other hand, professional-level DTF printers are designed for demanding users and commercial applications. They boast advanced features like higher printing resolutions, larger work areas, and enhanced ink options, ensuring superior print quality and longevity. These pro-level machines often include automated functions and advanced software controls, making them faster and more efficient for bulk production or specialized dtf printing services.

– Definition and basic working principle of DTF (Direct to Fabric) printing

Direct to Fabric (DTF) printing is a cutting-edge technique that allows for high-quality printing directly onto various fabric surfaces. This process involves transferring ink from a digital image onto a fabric medium, creating vibrant and durable designs. The key advantage of DTF lies in its ability to produce complex artwork with precision and detail, making it ideal for everything from custom apparel to home décor items.

The basic working principle of DTF printing equipment revolves around the use of UV light to cure the ink instantly as it makes contact with the fabric. This technology enables the production of precise, full-color prints on a diverse range of materials, including cotton, polyester, and nylon. After the initial print, heat presses are often used to permanently fuse the ink into the fabric fibers, ensuring durability and colorfastness. With DTF printing, users can create custom designs with intricate details and achieve outstanding results, making it a popular choice among both entry-level enthusiasts and professional printers.

– Types of DTF printers: Entry-level vs Professional models

In the realm of DTF (Direct to Fabric) printing equipment, the market offers a diverse range of options catering to both entry-level and professional users. Entry-level printers are ideal for hobbyists, small businesses, or those new to DTF printing. These models often come at more affordable price points, making them accessible. They typically feature basic functionalities like standard print resolution, limited material compatibility, and simpler design software. However, they provide a solid foundation for learning and experimenting with DTF transfers, such as creating custom DTF logo transfers or personal designs to apply on various fabrics.

On the other hand, professional-level DTF printers are designed for demanding users seeking advanced capabilities. These models boast higher print resolutions, extended material support, and more robust build quality. They often come with features like customizable color profiles, automatic registration systems, and the ability to upload your own gang sheet designs, enabling precise and repeatable printing. With these printers, creating high-quality, intricate custom DTF transfers for commercial applications or specialized fabrics becomes feasible. The choice between entry-level and pro models depends on individual needs, budget, and the complexity of the DTF transfers one intends to create.

DTF printing equipment has evolved to cater to both hobbyists and professionals, offering diverse options for various skill levels. By understanding the distinctions between entry-level and pro-level machines, users can make informed decisions based on their expertise and desired output. Whether for personal projects or commercial ventures, the right DTF printer promises to unlock creative possibilities, allowing designers to transform their vision into tangible, high-quality fabric art.